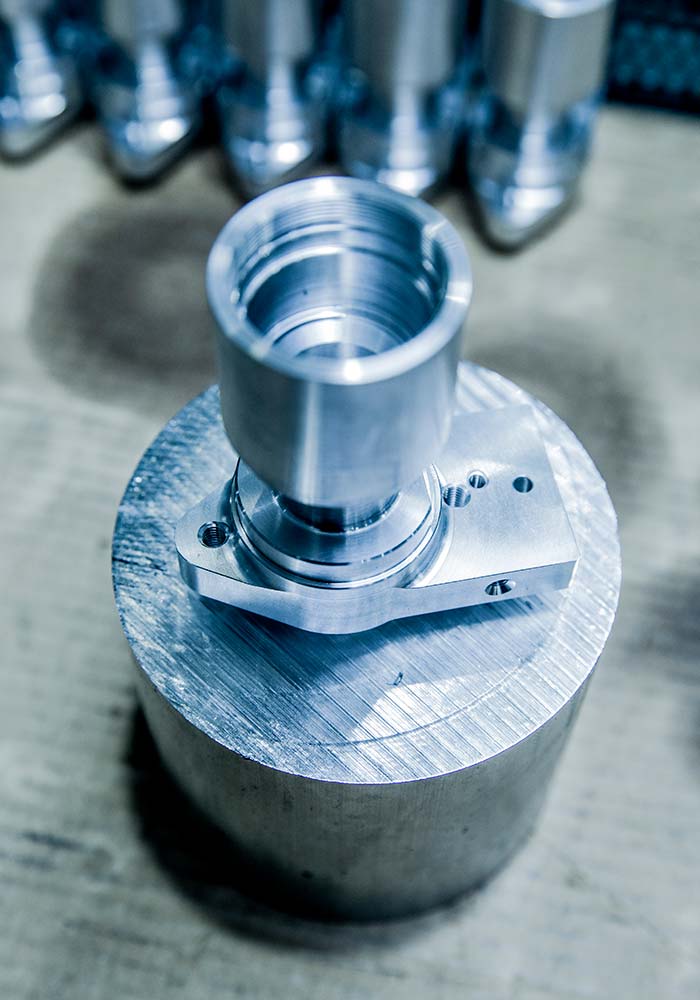

Precision machining for performance

Thanks to our production capacity and know-how, we manufacture precision mechanical parts for a wide variety of leisure equipment. Our machining processes ensure excellent dimensional accuracy and repeatability, regardless of technical constraints.

Custom machined parts for a variety of needs

We work with a wide range of materials, including aluminium, steel, stainless steel and other metal alloys, as well as plastics, to offer durable, high-performance solutions. Our production capacity enables us to manufacture a wide range of parts, from structural components to fastening and transmission systems. The most frequently manufactured components include :

- Essential mechanical parts: casings, supports, chassis and other elements contributing to the structure and robustness of equipment.

- Assembly components: all parts ensuring the connection and movement of mechanical systems.

- Highly technical components requiring precision machining to guarantee optimum performance and increased service life.

High-performance machinery

The Groupe ABCM relies on high-performance, diversified machinery to offer precision machining solutions tailored to the needs of the leisure industry. Our workshops are equipped with modern machining centres for precise turning, milling and grinding operations. We master multi-axis machining (3 to 5 axes) to manufacture parts with complex geometries, while guaranteeing optimum repeatability.

Our workshops are equipped with modern machining centres for precise turning, milling and grinding operations. We work with our customers right from the design phase to optimize the manufacture of parts and guarantee their compliance with industry requirements.